We have already laser cut our type from

A Life in Letterpress

Use of Univers

Printing processes and techniques

Experimental print using the type forme upside down to show the 'feet' of the type:

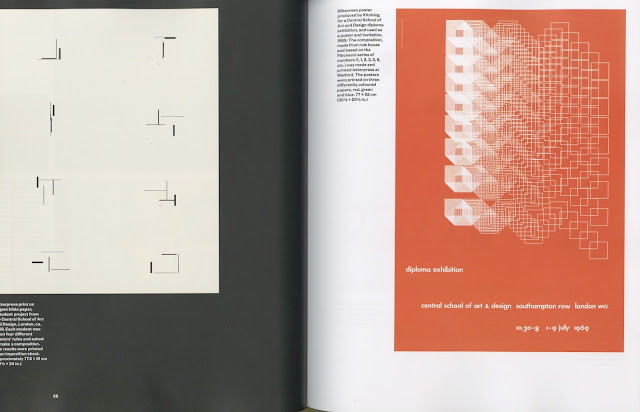

Experimental prints using metal furniture, normally used for spacing, which was cut to type height and then printed and then overprinted in a series of black and greys.

Composition to the right of the page was a student project. Each student was given four different printers' rules and asked to make a composition:

Peace - The hand showing the 'peace' symbol was visualised using typographic furniture.

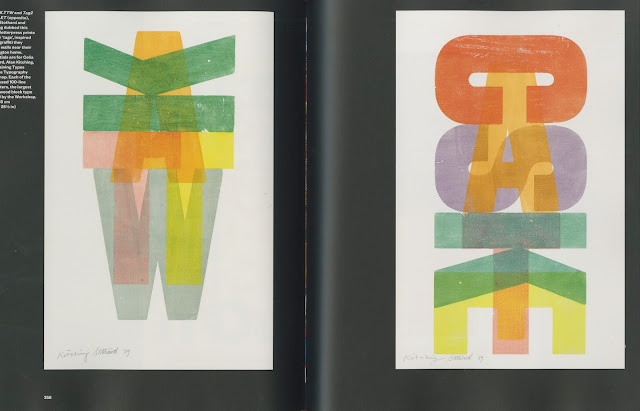

Big magazine number 7. Big's art director Vince Frost commissioned Kitching to produce woodletter artwork.

Promotional poster:

Layering: